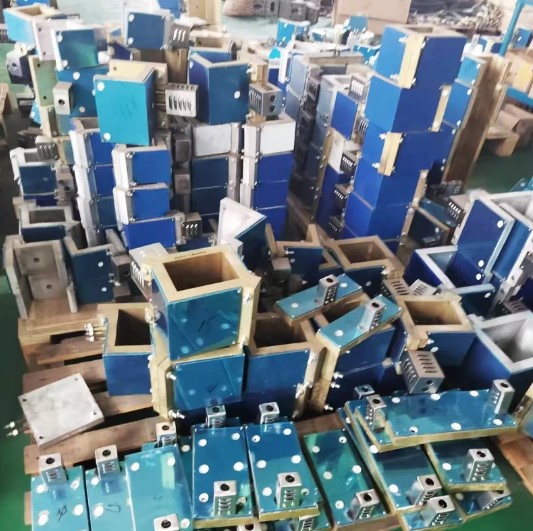

Cast bronze Heater

The cast copper heater uses tubular electric heating elements as the heating body and insulator,

in accordance with various drawing requirements. The tubular electric heating element is bent into

the required shape and then placed in the mold to be formed by centrifugal casting. After further precise

processing by machine tools, the required cast copper heater is obtained.

Its advantages are that it can closely interlock with the heated object, with a high-temperature working

temperature up to 800℃, fast heating, uniform heating, good conductivity and anti-pollution. Long service life,

safe and reliable. It is selected as one of the most ideal high-temperature resistant heaters in the heater.