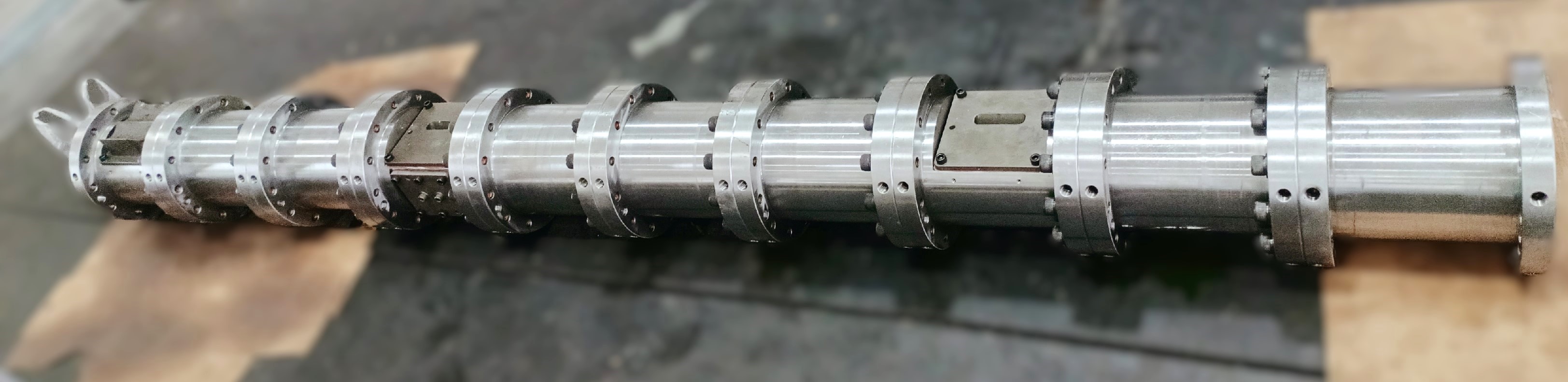

screw barrel

feeding barrel, venting barrel, closed barrel,side feeding barrel, and liquid injection barrel

The barrel is one of the core components of the twin-screw extrusion system, working in coordination with the screws to jointly achieve the plasticizing,

mixing and extrusion of materials. Its structural design and material selection directly affect the processing efficiency, wear resistance and application range of the equipment.

We offer a variety of opening design types (such as feeding ports, venting ports, side feeding ports, and liquid injection ports) to meet the feeding, venting, or additive injection

requirements of different materials.

Material selection and wear-resistant design

The barrel needs to with stand high temperatures, high pressures and material friction.

Common material solutions include:

-Basic solution:

45 # steel + C-shaped wear-resistant bushing, high cost performance, suitable for general plastic processing.

-Enhanced plan:

Bimetallic bushings (such as α101 iron-chromium-nickel carbide steel) : With a surface hardness of HRC60-64, they are resistant to glass fiber wear and are used to reinforce composite materials.

Nitrided steel 38CrMoAl: Strong corrosion resistance, suitable for corrosive materials such as PVC.

Special alloys: 316L stainless steel (food-grade anti-corrosion), powder nickel-based alloy (ultra-high wear resistance and corrosion resistance), used in high-end or special working conditions.

To save costs, large machine barrels often adopt a composite structure with an inner wear-resistant alloy layer and a common steel outer jacket