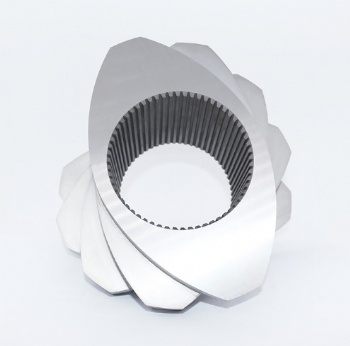

Conveying screw elements

Conveying Screw Elements:

Forward screw elements: The pitch is consistent with the extrusion direction, achieving efficient conveying. The larger the lead, the higher the output and the shorter the residence time

(suitable for heat-sensitive materials or exhaust sections).

Reverse screw elements: Hinders forward flow, prolongs residence time, increases filling degree and pressure, and enhances mixing effect (commonly used before the melting section or

the venting section)

Shearing element (kneading block)

Mechanism of action: By generating high shear force through staggered angles (30°, 45°, 60°, 90°), it achieves the dispersion and mixing (crushing of particles) and

distribution and mixing (component exchange) of materials.

Performance

The misalignment Angle ↑ → distributed mixing ↑, but the optimal dispersed mixing is achieved at 45°

Thickness ↑ → shear force ↑, but uniformity of mixing ↓

Application scenarios: Melting section pressurization, mixing section enhanced dispersion (such as glass fiber or carbon black filling)

Mixing element (TME)Grooves are made on the screw ribs (straight teeth/helical teeth), connecting adjacent screw grooves to facilitate longitudinal exchange

.

Advantages: High shear rate + low building pressure capacity, suitable for distributed mixing (such as color masterbatch dispersion or low-viscosity additive blending)

Material and durability

High-speed tool steel (W6Mo5Cr4V2) : Economical and universal;

Nitrided steel (38CrMoAlA) : Corrosion-resistant;

High-performance alloys: tungsten carbide (WC) alloy (with wear resistance increased by 7-8 times), Wr5 powder alloy (mainstream in Europe and America, with wear

resistance increased by 4-5 times),

suitable for highly abrasive fillers (such as glass fiber or minerals)

Process technology: Hot isostatic pressing (HIP) molding → Enhancing density and lifespan